Industrial valves play a crucial role in managing the flow of liquids, gases, and slurries across various industries. They serve as essential control mechanisms that enable efficient operation, safety, and reliability in processes. Understanding the different types of industrial valves and their specific applications is vital for selecting the right valve for your operational needs. In this article, we will explore the most common types of industrial valves, their features, and the applications for which they are best suited.

What Are Industrial Valves?

Industrial valves are mechanical devices that regulate, direct, or control the flow of fluids and gases within a system. They can be found in pipelines, tanks, and other systems and come in various designs, each suited for different functions. The primary purpose of valves is to control the flow and pressure of the media passing through them.

Key Types of Industrial Valves

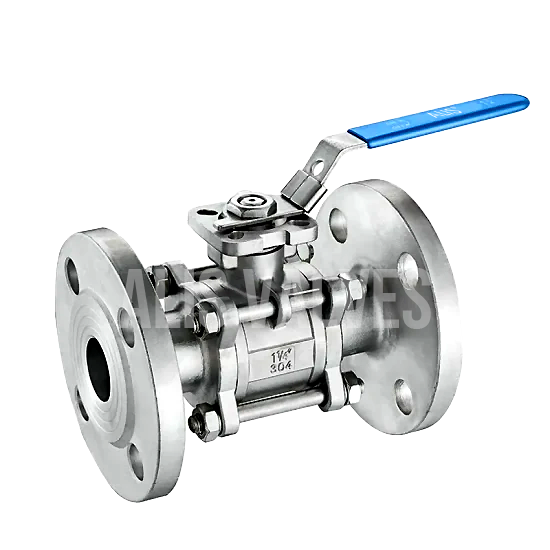

1. Ball Valves

Ball valves are one of the most widely used types of industrial valves. They feature a spherical disc (the “ball”) with a hole in the center. When the valve is turned, the ball rotates to either allow or block the flow of fluid.

Features:

- Quick and easy operation with a 90-degree turn.

- Excellent sealing capabilities, minimizing leakage.

- Suitable for high-pressure and high-temperature applications.

Applications: Ball valves are commonly used in oil and gas, chemical processing, water treatment, and HVAC systems, where a reliable and tight shut-off is essential.

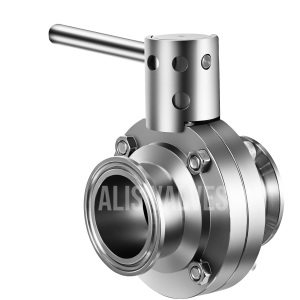

2. Butterfly Valves

Butterfly valves consist of a circular disc that pivots on a shaft. When the valve is opened, the disc rotates to allow fluid flow, and when closed, it blocks the flow.

Features:

- Lightweight and compact design.

- Cost-effective, especially for larger pipes.

- Low pressure drop when fully open.

Applications: Butterfly valves are often used in water distribution, wastewater treatment, and HVAC applications, where space and cost are concerns.

3. Gate Valves

Gate valves are designed for on/off control of fluid flow. They operate by raising or lowering a gate (a flat disc or wedge) to open or close the flow.

Features:

- Minimal pressure drop when fully open.

- Suitable for high-pressure applications.

- Provides excellent flow control over long distances.

Applications: Gate valves are widely used in oil and gas pipelines, water supply systems, and chemical processing, where the ability to isolate sections of a pipeline is crucial.

4. Globe Valves

Globe valves are primarily used for regulating flow. They feature a movable disk (the plug) that can be raised or lowered to control the flow of fluid.

Features:

- Excellent throttling capabilities.

- Suitable for high-pressure and high-temperature applications.

- Can handle various media types.

Applications: Globe valves are commonly used in power generation, oil and gas, and chemical processing industries, where precise control over fluid flow is necessary.

5. Check Valves

Check valves, also known as non-return valves, are designed to prevent backflow in a system. They allow fluid to flow in one direction while automatically closing if the flow reverses.

Features:

- Automatically prevent backflow without manual intervention.

- Available in various designs, including swing and lift types.

Applications: Check valves are used in water and wastewater treatment, pump systems, and heating applications to maintain system integrity and prevent damage.

6. Pressure Relief Valves

Pressure relief valves are safety devices that prevent over-pressurization in a system. They automatically open to relieve pressure when it exceeds a predetermined level.

Features:

- Protect equipment from damage due to excessive pressure.

- Available in various designs, including spring-loaded and pilot-operated.

Applications: These valves are essential in various industries, including oil and gas, chemical processing, and steam systems, where maintaining safe operating pressures is critical.

7. Actuated Valves

Actuated valves are controlled remotely using electric or pneumatic actuators. They enable automated control of valve operation, making them ideal for complex systems.

Features:

- Allows for remote operation and automation.

- Improves efficiency and reduces the need for manual intervention.

Applications: Actuated valves are widely used in automated systems, such as those found in manufacturing, water treatment, and oil and gas, where precise control is required.

8. Solenoid Valves

Solenoid valves are electromechanical devices that control the flow of liquids or gases. They use an electromagnetic coil to open or close the valve when energized.

Features:

- Fast response time for precise control.

- Compact design, suitable for limited spaces.

Applications: Solenoid valves are commonly used in automated systems, irrigation, and HVAC applications, where quick and reliable actuation is needed.

Selecting the Right Valve Type

Choosing the right type of industrial valve depends on several factors, including the medium being controlled, pressure and temperature conditions, and the specific application requirements. Here are some key considerations:

- Fluid Type: Consider whether the fluid is a liquid, gas, or slurry, and whether it is corrosive or hazardous.

- Pressure and Temperature: Ensure that the valve can handle the maximum pressure and temperature conditions of the application.

- Flow Control Needs: Determine whether you need simple on/off control or precise throttling capabilities.

- Space Constraints: Assess available space for installation, as some valve types may require more room than others.

- Automation Requirements: If automation is needed, consider actuated or solenoid valves for efficient control.

Conclusion

Industrial valves are essential components that facilitate the smooth operation of various industrial processes. Understanding the different types of valves and their specific applications is crucial for selecting the right valve for your needs. From ball and butterfly valves to pressure relief and solenoid valves, each type serves a unique purpose, making it important to choose wisely based on your operational requirements.

At Alis Valves, we offer a comprehensive range of high-quality industrial valves designed to meet the diverse needs of industries worldwide. Whether you require valves for oil and gas, water treatment, or chemical processing, our expert team is here to assist you in finding the right solution. Explore our offerings today and ensure your operations run smoothly and efficiently.