Construction projects face mounting pressure to deliver exceptional results within tight deadlines and budgets. Every structural element must be precisely planned and executed, particularly reinforcement steel (rebar) that forms the backbone of concrete structures. Errors in rebar installation can compromise structural integrity, leading to costly repairs, project delays, and safety concerns.

Rebar modeling services have emerged as a critical solution for construction professionals seeking to eliminate guesswork and minimize costly mistakes. These specialized services use advanced 3D modeling technology to create detailed, accurate representations of reinforcement steel before construction begins. By investing in professional rebar modeling, construction teams can identify potential issues early, streamline installation processes, and deliver projects with greater confidence.

The construction industry has witnessed a significant shift toward digital modeling solutions, with rebar modeling services leading the charge in improving project outcomes. These services bridge the gap between design intent and field execution, ensuring that every piece of reinforcement steel is positioned correctly from day one.

What is Rebar Modeling?

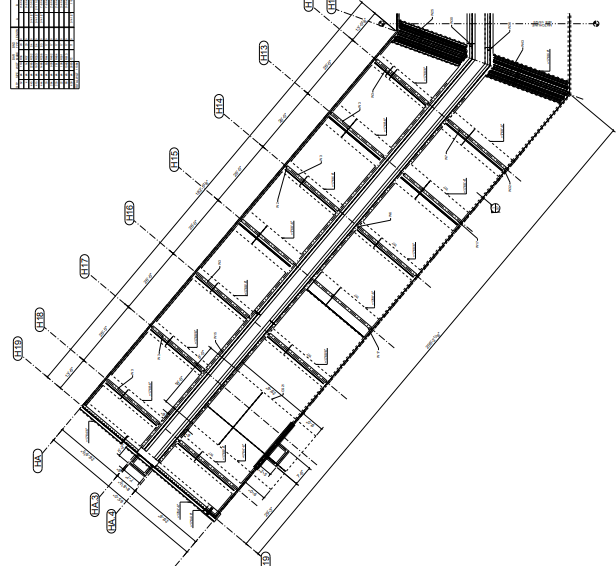

Rebar modeling involves creating detailed 3D digital representations of reinforcement steel within concrete structures. This process goes far beyond traditional 2D drawings, providing construction teams with comprehensive visual guides that show exact placement, spacing, and configuration of every rebar element.

Professional rebar modeling services utilize sophisticated software platforms such as Tekla Structures, Revit, and AutoCAD to develop these detailed models. The modeling process begins with architectural and structural drawings, which are carefully analyzed to understand design requirements and structural loads. Experienced modelers then translate these specifications into precise 3D representations that account for every bend, splice, and connection point.

The modeling process incorporates industry standards and building codes to ensure compliance throughout the project. Modelers consider factors such as concrete cover requirements, bar spacing regulations, and connection details that might be overlooked in traditional planning approaches. This comprehensive approach results in models that serve as reliable roadmaps for field installation teams.

Advanced rebar modeling services also integrate clash detection capabilities, identifying potential conflicts between reinforcement steel and other building systems before construction begins. This proactive approach prevents costly field modifications and ensures smooth project execution.

Benefits of Rebar Modeling Services

Enhanced Accuracy and Precision

Rebar modeling services deliver unmatched accuracy by eliminating the interpretation errors common with traditional 2D drawings. Field crews receive clear, detailed visual guides that show exactly where each piece of reinforcement belongs, reducing the likelihood of placement mistakes that can compromise structural integrity.

The precision offered by 3D models extends to quantity calculations and material optimization. Accurate material lists ensure that projects order the correct amounts of reinforcement steel, preventing delays caused by material shortages or excess waste from over-ordering.

Significant Reduction in On-Site Errors

Construction teams using rebar modeling services report substantial decreases in field errors and rework. The visual clarity provided by 3D models helps installers understand complex reinforcement patterns, reducing confusion that often leads to mistakes during construction.

When errors do occur, they’re typically identified and resolved much faster thanks to the detailed reference models. This rapid problem-solving capability keeps projects on schedule and prevents small issues from escalating into major problems.

Cost Savings and Budget Control

The financial benefits of rebar modeling services extend throughout the entire project lifecycle. By identifying potential issues during the modeling phase, construction teams avoid expensive field modifications that can significantly impact project budgets.

Material waste reduction represents another significant cost advantage. Accurate modeling enables precise material ordering, minimizing excess steel purchases while ensuring adequate supply for installation needs. Labor efficiency improvements also contribute to cost savings, as workers can complete installations more quickly when working from clear, detailed models.

Improved Project Timelines

Rebar modeling services accelerate project schedules by streamlining both planning and execution phases. The detailed models enable faster field installations, as crews spend less time interpreting drawings and more time on productive work.

Pre-fabrication opportunities become more apparent with detailed 3D models, allowing contractors to prepare reinforcement assemblies off-site for faster field installation. This approach can significantly reduce on-site labor requirements and compress project schedules.

Enhanced Collaboration and Communication

Professional rebar modeling services improve communication between all project stakeholders. Architects, engineers, contractors, and field crews can reference the same detailed models, ensuring everyone works from consistent information.

The visual nature of 3D models makes it easier to communicate complex reinforcement requirements to field teams, regardless of their experience level with traditional construction drawings. This improved communication reduces misunderstandings and helps ensure proper installation.

Choosing the Right Service Provider

Selecting the appropriate rebar modeling service provider requires careful evaluation of several key factors that directly impact project success.

Experience and Expertise

Look for providers with extensive experience in projects similar to yours. Commercial, residential, and industrial projects each present unique challenges that experienced modelers understand and can address proactively. Review the provider’s portfolio to ensure they have successfully completed projects of comparable size and complexity.

Consider the technical expertise of the modeling team, including their familiarity with relevant building codes and industry standards. Experienced modelers bring valuable insights that can improve both model accuracy and field installation efficiency.

Technology and Software Capabilities

Evaluate the technology platforms and software tools used by potential service providers. Leading rebar modeling services utilize industry-standard software that integrates well with other project management and design tools. Compatibility with your existing workflows can significantly impact project efficiency.

Ask about the provider’s ability to deliver models in multiple formats, ensuring compatibility with your team’s preferred software platforms. Some projects may require specific file formats or integration with particular construction management systems.

Client References and Success Stories

Request references from recent clients with projects similar to yours. Speaking directly with past clients provides valuable insights into the provider’s communication style, delivery reliability, and problem-solving capabilities.

Review case studies and success stories that demonstrate the provider’s ability to deliver measurable improvements in accuracy, cost savings, or schedule compression. These examples can help you understand the potential value of their services for your specific project.

Support and Communication

Assess the provider’s approach to ongoing support and communication throughout the project. Effective rebar modeling services maintain regular contact with project teams, providing updates and addressing questions promptly.

Consider the provider’s availability for field support and their willingness to make revisions when design changes occur. Construction projects often require model updates, and responsive service providers can adapt quickly to keep projects on track.

Maximizing Your Investment in Professional Modeling

Rebar modeling services represent a strategic investment in construction accuracy and efficiency. The benefits of improved precision, reduced errors, and enhanced collaboration far outweigh the initial costs, particularly on complex projects where reinforcement detailing plays a critical role.

Construction professionals who embrace these advanced CAD drawing services position their projects for greater success while building competitive advantages in an increasingly demanding market. The technology and expertise offered by professional rebar modeling services continue to evolve, providing even greater value for forward-thinking construction teams.

By partnering with experienced rebar modeling services, construction professionals can focus on what they do best while ensuring that every reinforcement detail is planned, modeled, and executed with precision. This collaborative approach leads to stronger structures, satisfied clients, and successful project outcomes that build lasting business relationships.