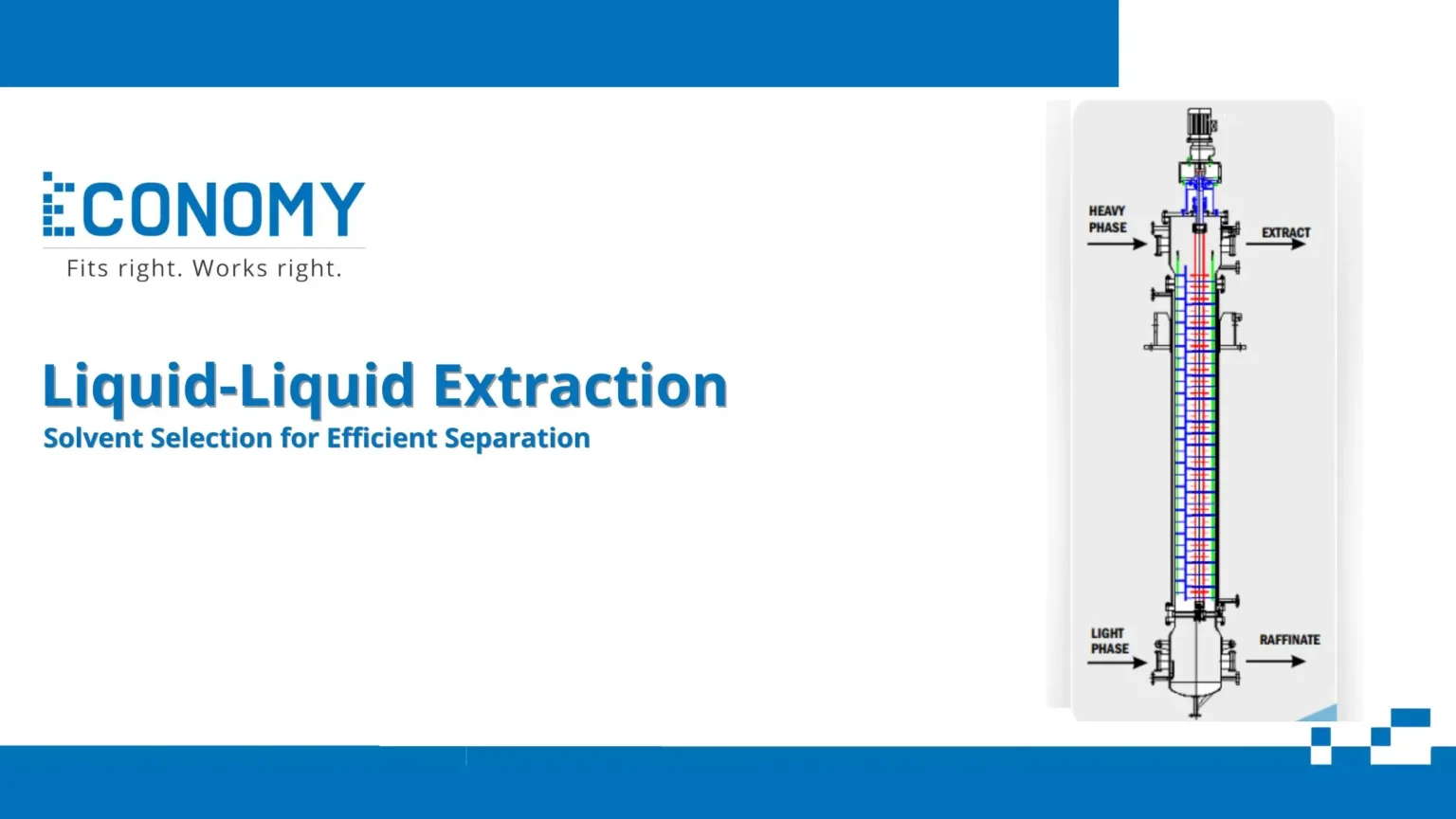

Liquid-liquid extraction (LLE), also known as solvent extraction, is a widely used separation technique in both industrial and laboratory processes. It involves the transfer of a solute from one liquid phase to another, typically from an aqueous phase to an organic phase, based on differences in solubility. The efficiency of this process heavily depends on the choice of solvent. Selecting the right solvent is crucial because it determines the partitioning behavior of the solute, the selectivity of separation, and the overall effectiveness of the process.

Criteria for Solvent Selection

The ideal solvent for LLE must meet several key criteria:

- Selectivity: The solvent should have a high affinity for the solute relative to other compounds present in the mixture. This ensures efficient extraction and minimizes co-extraction of undesired compounds.

- Solubility: The solvent must be immiscible or only partially miscible with the aqueous phase to create two distinct layers. Complete immiscibility is preferred to allow easy separation of the phases after extraction.

- Volatility: A good solvent should be volatile enough to be easily removed from the extract by evaporation or distillation, but not so volatile that it poses excessive handling hazards or evaporation losses.

- Chemical Stability: The solvent should be chemically inert and stable under the extraction conditions, ensuring that it does not react with the solute or other components of the system.

- Toxicity and Environmental Impact: For safety and environmental reasons, the chosen solvent should have low toxicity and be environmentally benign if possible.

- Cost and Availability: Economic considerations often play a significant role in solvent selection, especially in industrial applications where large quantities are required.

Common Solvents Used in LLE

1. Ethyl Acetate

Ethyl acetate is a widely used solvent in liquid-liquid extraction due to its relatively low toxicity, moderate polarity, and ease of removal after extraction. It has a boiling point of around 77°C, making it easily recoverable by distillation. Ethyl acetate is especially effective for extracting moderately polar to non-polar compounds from aqueous solutions, such as organic acids, esters, and some alkaloids. Its partial miscibility with water (about 8% at room temperature) allows for effective phase separation, though care must be taken to ensure immiscibility at the desired extraction conditions.

Ethyl acetate’s popularity stems from its balanced properties — it is volatile but not excessively hazardous, providing a safe and environmentally acceptable solvent for many processes. It is commonly used in the pharmaceutical, food, and fragrance industries for purifying products and separating active ingredients from complex mixtures.

2. Dichloromethane (DCM)

Dichloromethane, or methylene chloride, is another highly effective solvent used in LLE, particularly for the extraction of non-polar to moderately polar compounds. DCM is fully immiscible with water and forms a distinct, easily separable organic phase. It is prized for its ability to dissolve a wide range of organic compounds, making it particularly versatile in laboratory settings.

DCM has a low boiling point of 39.6°C, which makes it easy to evaporate and recover. However, it is more toxic and has a greater environmental impact compared to solvents like ethyl acetate. Its use has decreased in some industries due to stricter regulations and safety concerns, but it remains widely used for processes that require highly efficient extraction of non-polar compounds.

3. Mixtures of Ethyl Acetate and Dichloromethane

In some cases, mixtures of ethyl acetate and dichloromethane are used to fine-tune the extraction process. By blending these solvents, users can adjust the polarity and solvency power to achieve better separation of complex mixtures. For instance, adding ethyl acetate to dichloromethane increases the polarity of the organic phase, making it more effective for extracting moderately polar compounds. Conversely, increasing the proportion of dichloromethane improves the extraction of less polar compounds. This flexibility is valuable in multi-component extractions where precise solvent properties are required for effective separation.

4. Diethyl Ether

Diethyl ether is a common solvents used in liquid-liquid extraction, known for its high volatility and excellent solubility for non-polar compounds. Its immiscibility with water makes it suitable for a wide range of extractions. Ether is often used in organic chemistry labs for extracting neutral organic compounds from aqueous mixtures, particularly in situations where a highly volatile solvent is desired.

However, diethyl ether has some significant drawbacks, including its flammability and tendency to form explosive peroxides over time. These safety concerns limit its use in industrial settings, but it remains a common solvent in laboratory-scale extractions due to its strong performance and ease of use.

5. Toluene

Toluene is a non-polar solvent commonly used in LLE for extracting hydrophobic compounds from aqueous phases. It is immiscible with water and has a boiling point of 110.6°C. Toluene is particularly effective for extracting aromatic hydrocarbons, oils, and lipophilic compounds. Its relatively low toxicity and moderate volatility make it a practical choice in industrial applications, especially in the petrochemical and pharmaceutical industries.

However, toluene is less commonly used in laboratory settings due to its relatively high boiling point and the availability of more easily recoverable solvents like dichloromethane or ethyl acetate.

6. Hexane

Hexane is another non-polar solvent frequently used for LLE, particularly for the extraction of oils, fats, and other hydrophobic compounds. It is fully immiscible with water and has a low boiling point (around 68°C), making it easy to evaporate after extraction. Hexane is particularly valued in the food and agricultural industries, where it is commonly used for extracting edible oils from seeds and other plant materials.

While hexane is an efficient solvent for non-polar compounds, its high volatility and potential environmental impact, particularly its role in the formation of ground-level ozone, have led to increasing regulation of its use in many regions.

Conclusion

The choice of solvent in liquid-liquid extraction is crucial for ensuring efficient and effective separation. Ethyl acetate, dichloromethane, diethyl ether, toluene, and hexane are some of the most commonly used solvents in this process. Each has its strengths and weaknesses, and the optimal choice depends on factors such as solute polarity, toxicity, volatility, and environmental impact.