Machine components are the fundamental elements that allow modern machinery to operate efficiently and reliably. From simple devices like gears and bearings to complex assemblies like hydraulic systems and electronic controls, understanding machine components is essential for engineers, manufacturers, and anyone involved in industrial operations. A deep knowledge of these components ensures optimal performance, reduces downtime, and extends the life of machinery.

What Are Machine Components?

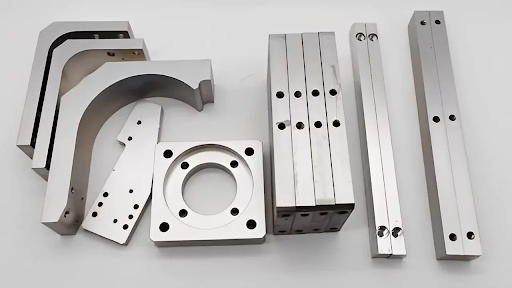

Machine components are individual parts or assemblies that make up a machine. They work together to perform specific functions, such as motion transmission, force application, or energy conversion. Each component, no matter how small, plays a critical role in ensuring that the machine operates smoothly and safely. Common examples of machine components include shafts, gears, bearings, couplings, springs, fasteners, and seals.

Importance of Machine Components

The performance and reliability of any machine depend on the quality and compatibility of its components. Poorly designed or substandard components can lead to breakdowns, increased maintenance costs, and safety hazards. Conversely, well-designed components that are precisely manufactured contribute to improved efficiency, longer operational life, and reduced energy consumption.

Key Types of Machine Components

1. Mechanical Components

Mechanical components are the backbone of most machinery. They include gears, pulleys, belts, chains, and couplings that transmit motion and force within the system. These components must be carefully selected based on load requirements, speed, and environmental conditions to prevent premature wear and failure.

2. Bearings and Shafts

Bearings reduce friction between moving parts, ensuring smooth rotation or linear movement. Shafts, on the other hand, transmit torque and rotational motion from one component to another. Choosing the right bearing and shaft combination is critical for maintaining alignment, minimizing vibration, and ensuring long-term durability.

3. Fasteners and Springs

Fasteners such as bolts, screws, and nuts hold components together securely, while springs provide force or absorb energy to maintain proper function. Though they may seem simple, these components are crucial for the stability and safety of machinery. Regular inspection and maintenance of fasteners and springs help prevent unexpected failures.

4. Seals and Gaskets

Seals and gaskets prevent leakage of fluids, gases, or contaminants, protecting internal components and maintaining efficiency. They are especially important in hydraulic and pneumatic systems where pressure and fluid integrity are critical. Selecting the appropriate material and design ensures that seals and gaskets perform reliably under varying temperatures and pressures.

5. Electronic Components

Modern machinery increasingly relies on electronic components such as sensors, actuators, and control systems. These components monitor and regulate machine operations, enabling automation and precise control. For example, temperature sensors, pressure switches, and programmable logic controllers (PLCs) are widely used in industrial equipment to maintain performance and safety.

Maintenance and Inspection

Proper maintenance of machine components is essential to prevent unexpected breakdowns. Regular inspections can identify wear, misalignment, or damage early, allowing for timely replacements or adjustments. Preventive maintenance not only extends the life of machinery but also reduces downtime and operational costs.

Integration with Industrial Solutions

Many industrial applications require the combination of machine components with packaging or material handling solutions. For instance, in automated production lines, components are integrated with systems like Wexxar packaging to ensure products are handled efficiently, safely, and consistently. Understanding how components interact with these systems is crucial for optimizing overall performance.

Conclusion

Machine components are the building blocks of modern machinery, each playing a vital role in ensuring efficiency, reliability, and safety. From mechanical parts like gears and bearings to electronic systems and seals, proper selection, installation, and maintenance are key to long-term performance. By understanding the purpose and function of each component, engineers and operators can improve machine longevity, reduce downtime, and achieve optimal operational efficiency. Integrating components with solutions such as Wexxar packaging further highlights the importance of cohesive systems in industrial environments. Investing in high-quality machine components from known sellers like Machine Parts Toolbox and maintaining them diligently ensures that machinery continues to perform at its best, supporting productivity and innovation.