In modern packaging operations, efficiency, speed, and presentation are key factors in delivering products that meet both business and consumer expectations. One indispensable tool in this process is the shrink film machine. Designed to wrap products tightly with shrinkable plastic film, these machines enhance product appearance, provide tamper protection, and improve shelf life. For new users, understanding how to operate a shrink film machine and its role within a packaging line is crucial for maximizing productivity and ensuring consistent results.

Whether you are packaging food, electronics, cosmetics, or promotional items, learning the basics of shrink film technology, setup, and maintenance can make the difference between an efficient packaging operation and frequent operational disruptions.

Understanding the Shrink Film Machine

A shrink film machine uses heat to shrink plastic film around products. The process typically involves three main steps: feeding the product into the machine, wrapping it with shrinkable film, and applying heat so the film tightly conforms to the product’s shape.

There are two primary types of shrink film machines:

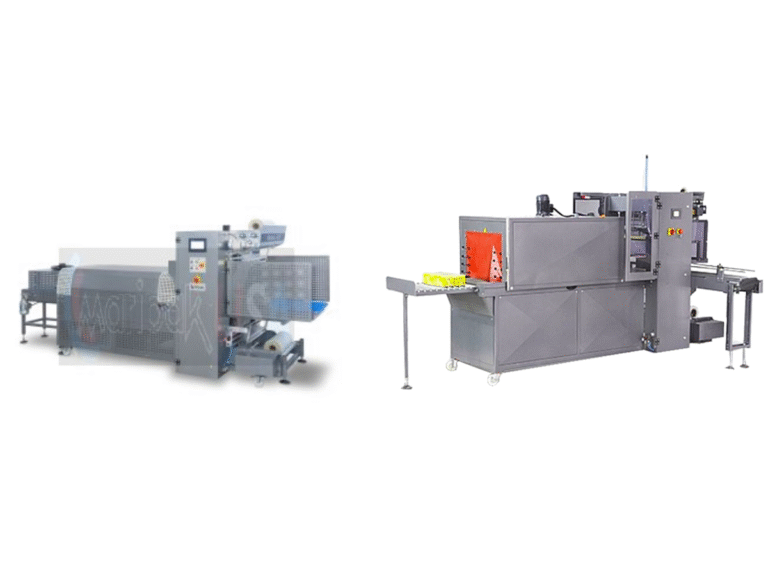

- Manual or Semi-Automatic Machines – Suitable for small to medium production volumes, these machines require some operator involvement to position and feed products. They are often used by startups or businesses with limited packaging demands.

- Automatic Machines – Designed for high-volume operations, these machines integrate with conveyor systems and reduce manual labor. They provide consistent wrapping, faster cycle times, and greater precision in shrink application.

Understanding your production requirements and choosing the appropriate type of shrink film machine is the first step toward achieving efficient packaging operations.

Key Features to Consider

When selecting a shrink film machine, several features can impact performance:

- Film Compatibility: The machine must accommodate different types of shrink films, such as polyolefin, PVC, or polyethylene. Each type has specific heat and tension requirements.

- Adjustable Heat Settings: Proper heat control ensures uniform shrinkage without damaging products.

- Speed and Throughput: Consider production volume to match the machine’s cycle rate with your operational needs.

- Safety Mechanisms: Features such as emergency stops, thermal protection, and insulated surfaces are crucial for operator safety.

These features help new users understand how the machine can be adapted to different products and production environments while ensuring safety and consistency.

Tips for New Users

Operating a shrink film machine efficiently requires a combination of technical understanding and practical experience. Here are essential tips for new users:

- Proper Training: Familiarize yourself with the machine’s operating manual, safety procedures, and maintenance requirements. Hands-on training ensures smooth operation and reduces the risk of accidents.

- Film Selection: Choose the correct type and gauge of shrink film for your products. Thicker films provide more protection, while thinner films are suitable for lightweight items.

- Heat Calibration: Adjust the temperature settings according to the film type and product sensitivity. Overheating can damage products, while insufficient heat may result in loose wrapping.

- Regular Maintenance: Keep the machine clean, inspect belts and rollers, and replace worn components promptly. Routine maintenance prevents breakdowns and extends the machine’s lifespan.

- Test Runs: Conduct test runs before full production to ensure proper shrinkage, alignment, and appearance. Minor adjustments during test runs can save time and reduce product waste.

Advantages of Using a Shrink Film Machine

Investing in a shrink film machine offers multiple benefits:

- Enhanced Product Presentation: Tight, uniform wrapping improves aesthetics and shelf appeal.

- Tamper Evidence: Shrink films act as a seal, enhancing product security.

- Reduced Packaging Waste: Proper film usage minimizes excess plastic while protecting products.

- Improved Storage and Transportation: Shrink-wrapped products are easier to stack and transport without damage.

These advantages contribute to operational efficiency, customer satisfaction, and long-term business growth.

Integration with Peripheral Equipment

To maximize efficiency, a shrink film machine often works in conjunction with peripheral equipment such as conveyors, product feeders, and labeling systems. This integration allows for a seamless packaging line where products move smoothly from one stage to the next without interruption.

- Conveyor Systems: Ensure products are delivered at a consistent speed to the shrink machine, reducing jams or misalignment.

- Product Feeders: Automate the process of positioning products for wrapping, reducing manual labor and improving accuracy.

- Labeling and Printing Equipment: Coordinate with shrink film application to apply labels correctly, enhancing branding and product information visibility.

By incorporating peripheral equipment into your packaging operation, businesses can achieve faster cycle times, reduce waste, and maintain a high level of product quality.

Conclusion

For businesses entering the world of automated packaging, a shrink film machine is an essential tool that combines efficiency, protection, and visual appeal. Understanding the machine’s features, integrating peripheral equipment, and following best practices ensures a smooth transition for new users. Whether you operate in the food, retail, or manufacturing sectors, investing in a quality shrink film machine and learning its proper operation can elevate your packaging process, safeguard your products, and create a professional, polished presentation that resonates with customers.