Acrylic is a highly versatile material used in a wide variety of applications, ranging from decorative items to functional components in industries such as automotive, architecture, and manufacturing. One of the most significant advantages of acrylic is its ability to be shaped and molded into different forms, with acrylic bending being one of the most common techniques employed. Professional acrylic bending services are crucial when precision, consistency, and quality are required. These services involve specialized equipment, expert knowledge, and experience to produce accurately bent acrylic pieces without compromising the material’s strength or clarity. In this article, we will explore the key benefits of professional acrylic bending services and why they are essential for businesses and industries that rely on acrylic components.

Understanding Acrylic Bending

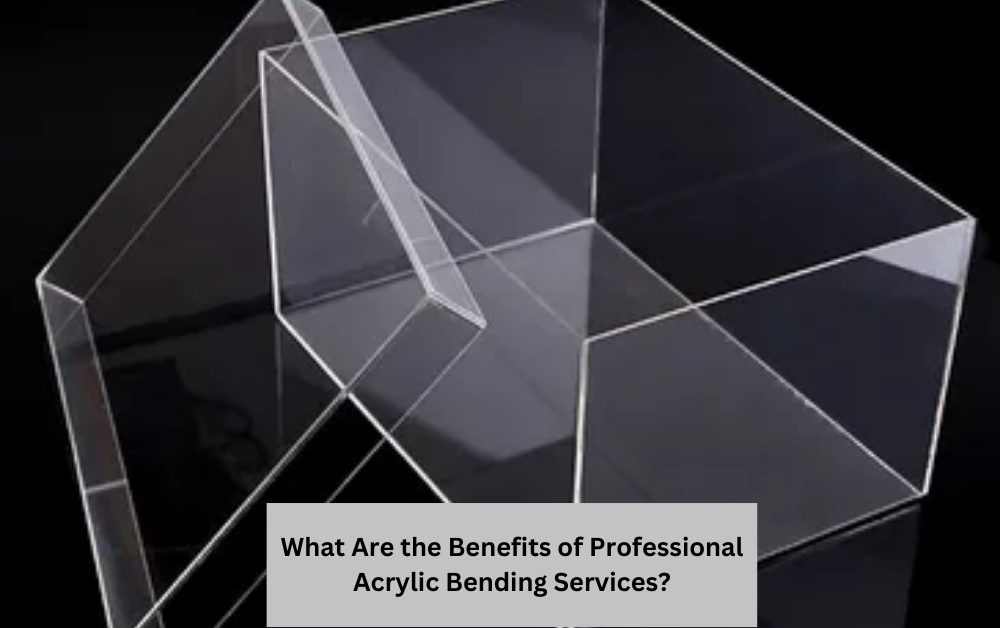

Before delving into the benefits, it’s important to understand what acrylic bending is and how it works. Acrylic bending is the process of applying heat to acrylic sheets to make them pliable so they can be bent into specific shapes. The heat softens the material, allowing it to be bent with precision. Once the acrylic has cooled, it retains its new shape, providing a strong and durable result. This technique can be used for a wide range of applications, from creating custom displays to functional industrial components.

While acrylic bending may sound simple, the process involves several key steps that require attention to detail. Professional acrylic bending services ensure that these steps are executed correctly, leading to high-quality results. The benefits of relying on professionals for acrylic bending services are numerous, and we will discuss them in detail below.

Note:- Acrylic Market, a top Acrylic Bending Services Dubai provider, created intricate and durable acrylic bends for a wide range of applications. Their commitment to quality ensured satisfaction on every project. Contact Acrylic Market now for professional acrylic bending services tailored to your needs and specifications.

High Precision and Accuracy in Bending

One of the primary benefits of using professional acrylic bending services is the high level of precision and accuracy that can be achieved. Acrylic components often need to meet specific dimensions or angles to fit seamlessly within a larger structure. For example, when creating custom signage, display cases, or protective covers, the acrylic pieces must be bent at exact angles without any imperfections.

Professional acrylic fabricators use specialized equipment and machinery that ensure precise bending. These machines are calibrated to handle the material with utmost care, producing bends with high consistency across multiple pieces. This level of precision is difficult to achieve with DIY methods or inexperienced fabricators, where inaccuracies in bending can result in gaps, weak spots, or structural flaws.

Moreover, expert fabricators can bend acrylic sheets with complex curves and angles that would be impossible for untrained individuals to replicate. This capability makes professional acrylic bending services the ideal choice for customized and intricate designs.

Consistent Quality and Durability

Another significant advantage of professional acrylic bending services is the consistent quality and durability of the final product. Acrylic is known for its optical clarity, strength, and weather resistance, but improper handling or bending can lead to defects like cracking, warping, or discoloration. When acrylic is not bent properly, it can lose its structural integrity and aesthetic appeal.

Professional acrylic bending services ensure that each piece is handled with care, and the proper bending techniques are applied to maintain the material’s original strength and clarity. The use of advanced bending tools and temperature controls ensures that the acrylic does not become overly brittle or weak during the process. As a result, the final product retains its high-quality appearance and durability, even after repeated use or exposure to environmental factors.

Furthermore, professionals take additional steps to reinforce the acrylic where necessary, ensuring that the finished product can withstand mechanical stress or impact. This is especially important for applications like automotive parts or outdoor signage, where acrylic components must endure challenging conditions over time.

Customization Options for Unique Designs

Professional acrylic bending services offer the flexibility to create customized designs that meet specific project requirements. Whether the goal is to create unique displays for retail environments or to produce complex architectural features, professional bending services can bring these designs to life.

Acrylic bending allows for both simple and intricate designs, from gentle curves to tight angles. This versatility makes it an ideal solution for industries that require specialized components, such as signage manufacturers, display builders, or architects. Professional acrylic fabricators can work with clients to bring their ideas to life, providing custom solutions that match exact specifications.

Whether the project requires a single bent acrylic piece or a series of identical components, professional services ensure that each piece is consistent in size, shape, and finish. This level of customization would be difficult to achieve without professional expertise, especially when multiple components are required for a larger structure or display.

Time and Cost Efficiency

Another significant benefit of relying on professional acrylic bending services is the time and cost efficiency it offers. Acrylic bending requires specific skills and equipment, which many businesses may not have in-house. Attempting to perform bending processes without proper training or machinery can lead to wasted materials, longer production times, and an increased likelihood of errors.

By outsourcing acrylic bending to professionals, businesses can save valuable time and resources. Professional fabricators have the necessary tools and expertise to complete the project quickly and efficiently, reducing production times. Moreover, because they are experienced in handling acrylic, they can ensure that the process is done right the first time, minimizing waste and the need for rework.

For businesses that require large quantities of acrylic components, professional bending services also offer economies of scale. Fabricators can streamline the process and produce multiple components at once, lowering the per-unit cost of production. This cost-effective approach is ideal for companies that need to produce acrylic parts in bulk while maintaining high quality.

Safety and Risk Mitigation

When working with acrylic, safety is a critical concern. Acrylic sheets can become very hot during the bending process, and improper handling can lead to burns or other injuries. Additionally, if acrylic is bent too aggressively or with the wrong technique, it can crack or shatter, posing safety hazards.

Professional acrylic fabricators are trained in the proper safety procedures and use specialized equipment designed to minimize risks. They are familiar with the safety protocols for working with high temperatures and are equipped with the right tools to handle acrylic safely. By hiring professionals, businesses can ensure that the bending process is carried out safely, reducing the risk of accidents or injuries.

Moreover, professional acrylic bending services often come with insurance and warranties, providing an added layer of protection for clients. This gives businesses peace of mind knowing that any issues that arise during the bending process will be addressed quickly and efficiently, reducing potential financial losses or delays.

Expert Advice and Consultation

In addition to the physical bending process, professional acrylic fabricators offer expert advice and consultation to help businesses make informed decisions about their projects. For example, they can assist with material selection, helping clients choose the best type of acrylic for their specific application. This is especially valuable for clients who may be new to working with acrylic or those who need guidance on the best bending techniques for their designs.

Professional fabricators can also offer suggestions on how to improve the design or functionality of the acrylic components, taking into account factors like structural integrity, aesthetics, and ease of installation. Their experience and expertise in the field can help businesses avoid common pitfalls and ensure that their acrylic components perform optimally.

The Benefits of Partnering with a Professional Acrylic Bending Service Provider

Partnering with a professional acrylic bending service provider provides a range of advantages, including access to skilled technicians, advanced equipment, and high-quality materials. Businesses can rely on these services to achieve precise, durable, and customized acrylic components that meet their exact needs.

From offering guidance on design and materials to ensuring safe and efficient production processes, professional acrylic bending services help companies streamline their operations and produce top-quality products. The benefits of professional acrylic bending extend beyond just the bending process itself; they also encompass the overall efficiency and reliability of the project.

Conclusion

Acrylic bending is an essential process for creating custom, high-quality components across various industries. The benefits of professional acrylic bending services are clear—high precision, consistent quality, customization options, cost efficiency, safety, and expert consultation. By partnering with a professional acrylic fabricator, businesses can ensure that their acrylic components meet the highest standards of performance and durability. Whether it is for a single, unique piece or a large-scale production, professional acrylic bending services provide the expertise and resources needed to bring projects to life with precision and care.

For More Isightful Articles Related To This Topic, Feel Free To Visit: chemhubglobal